5-axis machining is a machining technology that enables efficient and highly accurate machining of complex three-dimensional shapes and large product prototypes.

This article explains the mechanism and types of 5-axis machining and their merits in large product prototyping, as well as details the key points for selecting a vendor and the request process.

For more information about Taiga, click here.Table of Contents

What is 5-axis machining? Mechanisms and Types

5-axis machining is a technology developed to efficiently machine complex three-dimensional shapes.

This section details the basic structure and types of 5-axis machining.

5-Axis Machining Mechanism

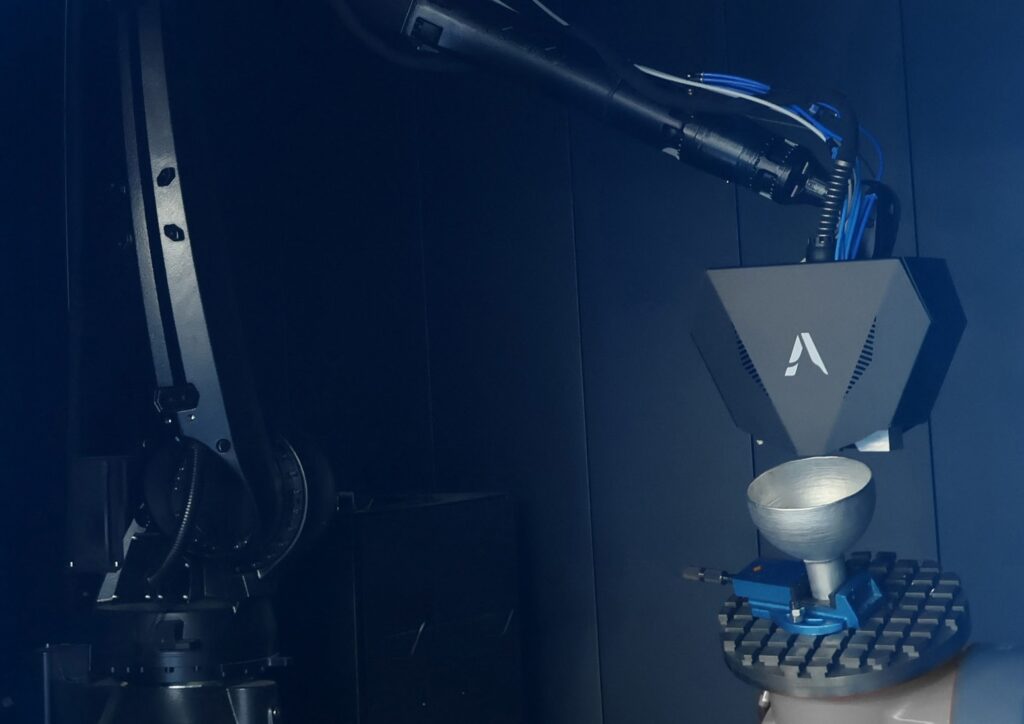

5-axis machining is an advanced cutting technology that controls two axes (rotation and tilt) in addition to the three linear axes (XYZ).

While maintaining spindle rigidity, the tool angle can be freely changed, and complex three-dimensional shapes and undercuts can be machined with high precision without re-fixturing.

In addition, productivity can be improved by reducing the set-up changeover process required for 3-axis machining, thereby reducing the machine's non-operating time.

5-axis machining is suitable for manufacturing gears, propellers, medical equipment parts, etc., and demand is growing in the aerospace and other fields.

Difference between simultaneous 5-axis machining and indexing 5-axis machining

The main difference between simultaneous 5-axis machining and indexing 5-axis machining lies in the way the axes operate.

Simultaneous 5-axis machining enables efficient machining of complex shapes and curved surfaces by simultaneously moving the XYZ axis and two axes of rotation and tilt.

On the other hand, in indexing 5-axis machining, positioning is first performed in the rotary and tilt axes, followed by machining in the XYZ axes.

Indexable 5-axis machining is easy to adjust for axis misalignment and is ideal for machining simple shapes, such as multi-face machining and drilling.

Advantages of using 5-axis machining for prototyping large products

5-axis machining helps reduce machining time and costs in prototyping large products.

Here are some specific advantages of 5-axis machining.

Reduced processing time

With 5-axis machining, multiple surfaces can be machined in a single chucking operation, greatly reducing the number of setup changes.

On the other hand, 3-axis machining is limited to the Z-direction, requiring additional jigs and frequent setups when machining intersecting holes or inclined surfaces from multiple directions.

Each time this is done, accuracy adjustments and inspections are required, which increases work time and labor.

In this respect, 5-axis machining has the great advantage of eliminating these processes and streamlining the manufacturing process.

High processing quality and accuracy

A major feature of 5-axis machining is its ability to machine complex shapes efficiently and with high precision.

The runout width of the spindle is reduced to 0.01 mm or less, enabling high-precision finishing with a surface roughness of Ra 0.8 μm or so, even for large workpieces.

Also, by tilting the workpiece or machine head, a shorter cutting tool can be used, which reduces tool flexure and improves accuracy and quality without reducing machining speed.

Reduced processing costs

5-axis machining reduces machining time and improves quality, thereby reducing machining costs.

While 3-axis machines required multiple special jigs to accommodate increasingly complex product shapes, 5-axis machines can perform multi-face machining using only standard jigs.

Eliminating special jigs has the advantage of stabilizing quality by reducing the risk of defects such as workpiece installation errors and jig errors.

As a result, it also leads to improved product functionality, such as component integration and weight reduction, and enables both cost reduction and quality improvement.

How to choose a contractor for prototyping large products with 5-axis machining

When requesting 5-axis machining for prototyping of large products, choose a supplier with the following points in mind.

Introduction of Machining Centers

Typical machining centers that support 5-axis machining are as follows

- Yamazaki Mazak:VERSATECH Series

- DMG Mori Seiki : DMU series

- Kitamura Machinery Corporation: Mytrunnion-4G

- Takeda Machinery Corporation:mu-V series

- FTV-500i: Otori Kikou Co.

- Eglo Corporation: E-32v

- Matsuura Instrument Manufacturing: MX-520

- Makino Milling Machine: V100S

Each of these features is briefly described below.

VERSATECH Series

The VERSATECH series is a 5-axis machining center specialized for machining large parts and complex shapes.

The BT50 taper spindle is used to achieve both high rigidity and high precision.

DMU Series

The DMU series offers both vertical and horizontal types and features high-precision control technology and automation functions.

We are particularly strong in complex 3D shapes and curved surface machining.

Mytrunnion-4G

Mytrunnion-4G features a space-saving design.

Suitable for small-lot production and parts machining that requires high precision.

mu-V series

The mu-V series features a highly rigid trunnion table with high tracking capability and high end-milling capacity.

It also offers high visibility during work and excellent workability.

FTV-500i

The FTV-500i is a machining center that excels in multi-face machining and cost performance, making it suitable for small-lot production and mass production of inexpensive products.

It has the advantage of being relatively inexpensive to implement.

E-32v

The E-32v is a compact, low-cost machining center that is also compatible with automation.

It is also suitable for companies that are introducing 5-axis machines for the first time.

MX-520

Despite its compact design, the MX-520 is a machining center that supports a maximum work size of Φ710 x H350 mm and an allowable workpiece mass of 200 kg.

V100S

The V100S is a machining center specialized for machining large parts and dies.

The slant-type spindle with a wide machining range and highly rigid structure supports large workpieces and heavy-load machining.

Processing Results

A vendor's processing track record is important in selecting a vendor.

Check whether the company can handle a variety of materials such as aluminum, stainless steel, copper, and brass, and whether it has the latest 5-axis machining centers and advanced technical capabilities.

Another point to check is whether the company has a processing track record similar to its proven industry and its own products.

Availability of design and prototype support

Many good 5-axis machining providers offer optimization assistance for 3D-CAD data.

Selecting a supplier that can present machining time and costs in advance through cutting simulation can reduce risk at the prototype stage.

Quality Control System

Quality control is also important in selecting a contractor. Specifically, ISO 9001 certification is a basic indicator.

Also, check whether high-precision measuring instruments (e.g., laser trackers and CMMs) are installed and whether automatic measurement data recording functions are in place.

Duration and cost of this production

Choose a vendor that understands the entire process from prototype to mass production and can provide a clear cost estimate.

It is also helpful to confirm the ability to handle small-lot production starting from one piece and high-mix production.

Availability of other processing methodologies.

In addition to 5-axis machining, products can be developed more efficiently by combining multiple machining technologies, such as 3D printers and laser cutting.

Choosing a supplier that can handle a wide range of processing methods will expand the possibilities for future product development.

Flow of requesting a prototype of a large product by 5-axis machining

The process of requesting a prototype depends on the vendor and whether it is an ongoing transaction.

The following is an example of a specific request process.

- Request for quotation (3D data submission)

- Discussion and presentation of quotation (clearly state breakdown of material costs and processing time)

- official order

- payment

- prototype manufacture

- Accuracy measurement (total inspection by CMM)

- delivery of goods

At the time of the request for quotation, size, shape, quantity and application, drawings and samples may be required, which should be prepared in advance.

Summary

5-axis machining shows its strength in the machining of complex and three-dimensional shapes, and is ideal for prototyping large products.

Attractive cost reductions due to shorter machining times and high-precision finishes have led to its adoption in a wide range of fields, including semiconductor parts and aerospace.

When hiring a fabricator for large prototypes in 5-axis machining, check the availability of a machining center, quality control system, and design and prototype support.

By utilizing 5-axis machining, we can meet diverse needs in product development and develop higher quality products.

If you are considering manufacturing high-precision components, please contact us.Taiga."Taiga is a free service that allows you to consult with experienced contractors.

We can efficiently proceed with the development of difficult or new parts, small-lot production, prototyping, and mass production while keeping costs low.

For more information about Taiga, click here.

0120-987-742

0120-987-742