Alex (Interviewer): Mr. Suzuki, thank you for sitting down with me today. To begin, could you share how you came to lead Plus Engineering?

Mr. Suzuki: Interestingly, my career didn't start in manufacturing at all. Engineering was a client of that bank, and when the founder fell ill, the company asked for help in finding a successor. I had never imagined becoming a manufacturing CEO, but I accepted-and here I am, now in my 16th year.

Alex: That's quite a leap-from finance to manufacturing. Did your banking background influence how you managed the company?

Mr. Suzuki: Absolutely. As a banker, I always envied manufacturing for its clarity: costs and prices are concrete, unlike in services. My banking experience helped me strengthen the company's foundation. Of course, employees were skeptical at first-"Can a banker really run a factory? Of course, employees were skeptical at first-"Can a banker really run a factory?"-but we earned each other's trust over time.

Alex: Over your years in manufacturing, how has the industry changed around you?

Mr. Suzuki: The most striking change is globalization. major manufacturers have shifted production overseas to cut costs, leaving fewer projects in Japan. On top of that, financial scrutiny has become stricter, and many small manufacturers face succession issues. Business closures and bankruptcies are increasingly common.

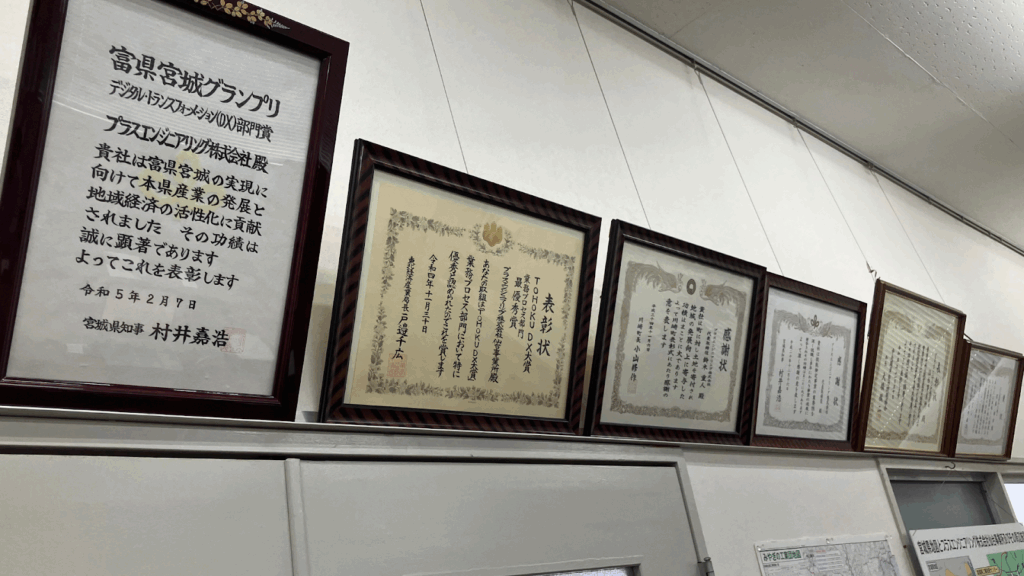

Alex: How has Plus Engineering adapted to this environment?

Mr. Suzuki: Rather than chasing cost reductions, we decided to pursue value creation. This often means complex, one-of-a-kind products that aren't found in catalogs. At the same time, we're improving efficiency: applying AI to shorten design and estimation processes, and running unmanned machining overnight to At the same time, we're improving efficiency: applying AI to shorten design and estimation processes, and running unmanned machining overnight to maximize utilization.

Alex: So your strengths are agility and added value.

Mr. Suzuki: Exactly. And those strengths have brought us opportunities with global electronics companies, semiconductor makers, food machinery firms And those strengths have brought us opportunities with global electronics companies, semiconductor makers, food machinery firms, medical institutions, and even aerospace clients.

Alex: That's quite diverse. do you have an example of a recent challenge you're proud your team overcame?

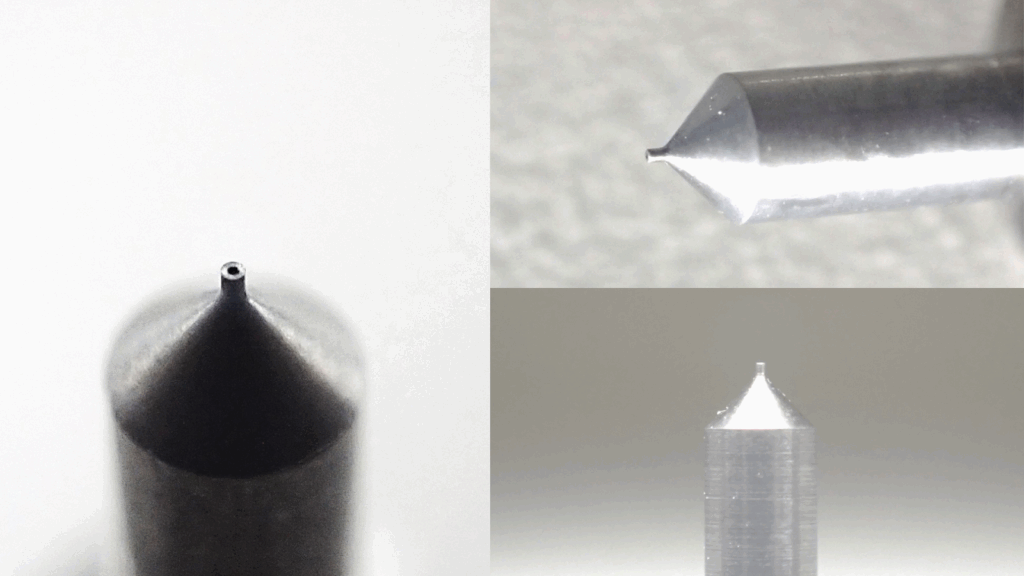

Mr. Suzuki: Yes. Traditionally, we specialized in components around 100 mm in size, mostly for electronics. It was challenging, but we succeeded. 're actively taking on projects requiring 1-micron precision, which raises the bar even further.

Alex: I imagine some customers try overseas suppliers but return to you later.

Mr. Suzuki: It happens. clients move production abroad, but when quality or reliability becomes an issue, they come back. It's not limited to one industry-this happens everywhere, because one faulty part can stop an entire production line.

Alex: Speaking of customers, do you find that they sometimes misunderstand what's possible in manufacturing?

Mr. Suzuki: Often. designers may create drawings with unnecessary complexity or unrealistic specifications. That's where we contribute our "wisdom of a parts maker" -practical knowledge built from decades across industries. -We propose alternatives, and customers appreciate that problem-solving.

Alex: It sounds like you're bridging the gap between design and manufacturing.

Mr. Suzuki: Yes. Too often they are separated. We try to connect them by suggesting improvements. Mr. Suzuki: Yes, they are separated.

Alex: If you could change one thing about the entire manufacturing industry, what would it be?

Mr. Suzuki: I'd make it easy to instantly identify the right partner for any task. But finding the right collaborator often takes enormous effort. If we could solve that, the entire industry would move faster.

Alex: And what about the bigger picture-how do you see supply chains evolving globally?

Mr. Suzuki: Current trade policies, especially U.S. tariffs, are reshaping logistics. This creates real risks: certain parts may no longer be sourced as before. We must stay alert and flexible to adapt quickly.

Alex: Looking far ahead, what do you imagine Plus Engineering will look like in 50 years?

Mr. Suzuki: I believe we'll maintain today's scale with perhaps half the workforce. But decision-making-the judgment-will remain human. Machines can calculate, but people must decide.

Alex: So even as technology advances, human creativity remains essential.

Mr. Suzuki: Exactly. In fact, companies that can combine advanced automation with human sensitivity and solution-proposing will survive. never change.

Alex: Finally, do you have a message for potential overseas partners?

Mr. Suzuki: For 50 years, we've specialized in custom manufacturing. We process around 10,000 unique items annually for 400 clients in Our integrated facility handles cutting, grinding, and EDM under one roof, enabling us to deliver complex, high-performance parts. And just as Taiga builds business through dialogue rather than simple quotations, we also build partnerships through conversation. We look forward to supporting global clients with our expertise.

0120-987-742

0120-987-742