CFRP

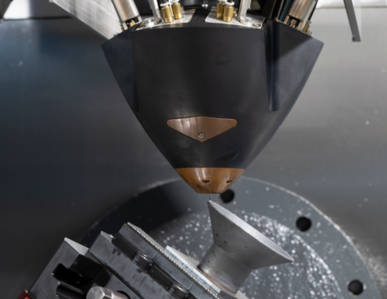

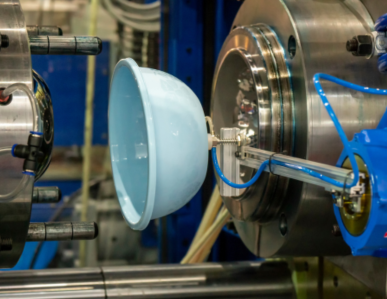

CFRP processing technology is used in the energy industry to produce lightweight, high-strength components. CFRP is significantly lighter than metal, has excellent corrosion resistance and vibration damping properties, and is stable even in high temperature and humidity environments. For this reason, CFRP is used in blade structural sections of wind turbines, auxiliary frames of gas turbines and generators, heat insulation panels, and vibration absorbing materials for equipment. It is also an excellent nonmagnetic material, making it suitable as a structural material around equipment where electromagnetic interference must be avoided.

Learn more about our technology.

0120-987-742

0120-987-742

![Important] Notice of Change of Company Name](https://57.182.158.32/wp-content/uploads/2025/09/Important-notice-300x214.png)